Solid vs. Engineered Wood: Best Hotel Vanity Material

A well-designed guest bathroom calls for a thoughtful selection of features and furnishings. Each has its unique role, but one of the quintessential elements is a vanity because it sets the mood and absorbs a lot of use. In most cases, you'll have to choose between solid wood and engineered wood. Depending on the hotel’s specific requirements, each offers unique advantages and disadvantages. Knowing the requirements will help you get the right materials and make the best decision for your property.

Elevate your guest bathroom with a stylish wood vanity—choose solid or engineered to fit your hotel's needs. Get yours today!

Difference between solid wood and engineered wood

Before we get into the details, there is one thing that needs explanation and that is definitions:

Solid Wood: Starting off with something straightforward, these types of vanities are crafted from blocks of genuine hardwood (such as oak, maple, and cherry) or occasionally softwood like pine, though it's rare for high-quality vanities. Each component, the frame, as well as the door panels, is completely composed of natural wood.

- Engineered Wood Products: Even though this section is a little more complex, it is still very simple to understand. As the name suggests, engineered wood products are made by using adhesives to bond wood fibers, particles, or veneers into a composite material. Among these, the following types are commonly used for vanities:

- Plywood: is made up of thin layers of wood veneer (plank) and glued together with the grain direction of each layer being perpendicular to that of the one below. This cross-graining makes it very strong and stable.

- MDF (Medium Density Fiberboard): Features fine wood fibers mixed with wax and resin and pressed into smooth, dense panels. It's very uniform and takes paint exceptionally well.

- Particleboard: Refers to chips, shavings, or even sawdust of wood mixed with resin, and pressed. It's usually the cheapest option. But when it comes to durability, it ranks the lowest-especially with moisture.

With the players in the game known, let's see how they stand up to hotel usage.

Why solid wood is great for hotel bathrooms

.webp)

It is impossible to overlook solid wood. Its beauty is timeless and has an authentic feel to it which a lot of the visitors value.

Choose Smart, Last Longer – Find out what makes a bathroom vanity stand the test of time in our latest post on top durable materials for hotel bathroom vanities.

- Natural Beauty & Character: Each solid wood vanity is different due to the ever varying grain patterns, knots and colors of the wood. This adds an element of luxury and class to your rooms, as each piece stands out.

- Durability (When Cared For): Unlike softwoods, high quality hardwoods are more durable. They create stunning pieces of furniture that can last for decades, provided they do not receive an excess of moisture. Good sealing and careful use eliminate this problem.

- Repairable: So long as the damage is not so pronounced, solid wood suffers little to no damage when it comes to scratches. Sanding and refinishing highly enhances the life of the vanity as well.

- Prestigious Feel: In the eyes of most people, wood evokes luxury. Solid wood is no different. For many, it is synonymous to quality craftsmanship and other elegant features which increases the perceived value guests have of the product.

The major concern is the change in water and humidity levels for solid wood which can yield catastrophic results in bathrooms. Should the wood not be sealed properly or the bathroom lacks ventilation, the wood may expand, contract, warp or crack. Therefore, maintenance and finishing greatly affect the longevity of durable wood vanities.

Why engineered wood Vanities are good choice for Hotels

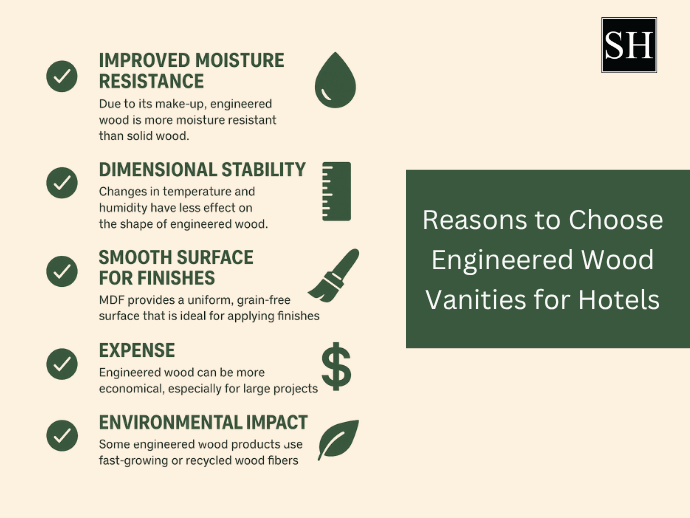

Given these advantages, engineered wood – especially high-grade plywood or MDF – has become the go-to selection for hotel vanities because of their ability to endure humid environments.

- Improved Moisture Resistance (More Often): This remains one of the most defining advantages. Due to its make-up, engineered wood (especially high-grade plywood and well-sealed MDF) quality is more moisture resistant than solid wood. It is not as prone to warping, cracking or expansion due to the steam and splashing commonly found in bathrooms. This gives it an edge when thinking about materials for hotel bathroom vanities.

- Dimensional Stability: Changes in temperature and relative humidity have less effect on the shape or size of parts of engineered wood than that of solid wood. As a result, doors and drawers are much less prone to sticking or widening gaps.

- Smooth Surface for Finishes: MDF, more than any other, has one of the most homogeneous surfaces, which is ideal for finishes. It gives a smooth surface devoid of any wood grain, unless veneer is applied (and even then, it can be buffed to perfection).

- Expense: Using engineered wood as opposed to solid hardwood is more economical, especially for larger projects like hotel renovations. This enhances the design of hotel bathrooms without losing too much in aesthetic value along with primary functionality.

- Environmental Impact (Shift): Created from reconstituted wood fibers or made from fast-growing, low-impact trees, some engineered wood products utilize these materials, making it environmentally friendly. In many cases, they cut down more, making them green.

In this context, it is vital to clarify that not all engineered wood is created the same. For example, low-quality particle boards are not likely to hold up well against moisture. However, high-grade plywood and well-treated MDF do remarkably well with vanities.

How to Choose the Right Hotel Bathroom Vanity

As you mull over the debate on solid wood vs. engineered wood vanities, consider these additional critical points:

- Your Hotel’s Style and Branding: What are the design goals for your hotel? Are they aiming for modern minimalism or rustic luxury? Solid wood may work for more heritage toward high-end natural or organic looks. On the other hand, engineered wood, particularly gloss or laminate covered boards, may fare better in sleek contemporary designs.

- Bathroom Environment: What is the ventilation like in your bathrooms? Do they have very high humidity? What is more challenging is the environment, the more a stable engineered wood might be preferred, or a very well-shielded solid wood that is resistant to moisture.

- Budget: Expecting to spend a little more on premium solid hardwood? That is the general consideration when it comes to surpassing engineered wood alternatives. We recommend balancing your design dreams with your financial reality.

- Maintenance Expectations and Lifespan: It's easy to determine the level of maintenance effort you're prepared to invest in the vanities. Consider also how long you expect them to last. While solid wood offers the option of refinishing, the perfect care required to avoid moisture damage makes it a concern. On the other hand, high-quality engineered wood offers excellent longevity by having less concern about warping compared to its counterparts.

- The Finish: The quality of the bathroom sealant, paint, or varnish is the first layer of protection against moisture; consequently, no matter what option you pick solid or engineered wood, the finish is crucial.

Solid Wood Vs. Engineered Wood Vanities : Final Comparison

Let's break it down with a simple table to highlight the main differences for hotel applications:

|

Feature |

Solid Wood Vanities |

Engineered Wood Vanities (Plywood/MDF) |

|

Aesthetics |

Natural beauty, unique grain, classic appeal |

Consistent, smooth (for paint), versatile |

|

Moisture Resistance |

Fair to Good (Highly dependent on sealing) |

Good to Excellent (Plywood/MDF well-sealed) |

|

Dimensional Stability |

Fair (Can expand/contract with humidity) |

Very Good (Less prone to warping) |

|

Durability (Core) |

Very Good (Hardwoods are strong) |

Good to Very Good (Quality plywood is strong) |

|

Surface Durability |

Depends on finish; can scratch/dent |

Depends on finish/veneer; can chip/scratch |

|

Repairability |

Good (Can be sanded/refinished) |

Fair to Limited (Depends on damage/finish) |

|

Cost |

Higher |

Generally Lower to Mid-Range |

|

Best for Paint |

Okay, but grain can show |

Excellent (Especially MDF for smooth finish) |

|

Weight |

Heavier |

Generally Lighter |

This comparison shows that while both have their merits, they excel in different areas crucial for Durable wood vanities for hotels.

Conclusion

So, what’s the final verdict in the solid wood vs. engineered wood vanity debate? The truth is-there’s no one-size-fits-all answer for every hotel.

Solid wood offers unmatched natural beauty and a premium feel. With proper sealing and good ventilation, it can last for years, making it ideal for luxury hotels or properties that emphasize heritage and authenticity.

On the other hand, engineered wood-especially high-quality plywood or well-sealed MDF-provides better moisture resistance, dimensional stability, and affordability. It’s a practical choice for high-traffic hotel bathrooms, particularly when modern finishes or painted surfaces are preferred.

Before making your decision, consider your hotel’s design theme, guest expectations, budget, and maintenance capacity. Understanding the key differences between solid and engineered wood will help you choose a vanity material that supports both your design vision and long-term durability.

- SOFT SEATING

- BATHROOM VANITY

- FIXTURE EQUIPMENT

- Hospitality Casegoods

- Hospitality outdoor furniture

- Senior living furniture

- Hotel reception desk

- High end contract furniture

- Premium Hotel Bedroom Furniture

- Custom commercial furniture

- Hospitality Furniture Manufacturers in Canada

- Leading Hotel Furniture Manufacturers in Canada

- Casegood manufacture canada

- Hotel Casegoods

CATEGORIES

FREQUENTLY ASKED QUESTIONS

RELATED BLOGS

The Ultimate Guide to Bathroom Vanities 2026

Sara Hospitality | Feb 05, 2026

Top USA Manufacturers of Wood Bathroom Vanities for Hotels

John Smith | Jan 22, 2026

Granite vs. Wood Vanities: Balancing Elegance and Durability for Hospitality

Sara Hospitality | Jan 12, 2026